Along with driving, resting, and spending time with household over the vacation recess, I used to be additionally very a lot wanting ahead to lastly having sufficient downtime to undertake Challenge Gravel–or “PRJCT GRVL,” to make use of the proper Gravelese. Properly, I’m happy to report it’s now full–although I did have to postpone it for a couple of extra days in an effort to rehabilitate the Cervino after my crash:

Please be aware that in doing so I prioritized expediency and security over aesthetics and period-correctness. The cockerpit I principally transferred over immediately from a earlier incarnation of the Faggin, and whereas I little question might have salvaged the unique bars and stem I figured when you crash important parts which might be over 40 years outdated it’s higher to be secure than sorry. (Don’t fear, I’ve nonetheless acquired the Tremendous File brake levers.) As for the tires, they’re 28mm Paselas, which ought to be extra sure-footed, and naturally they’re clinchers, which suggests they gained’t roll off as a result of they had been glued on by an fool. Lastly, you’ll be aware the double-sided pedals, which facilitate strolling whilst you’re ready for spouses and ambulances to reach–and the pedals I used to be utilizing once I crashed at the moment are damaged anyway:

Maybe sooner or later sooner or later I’ll try to revive somewhat extra class to the bike, however for the meantime I’m simply completely happy to have it rolling once more.

As for PRJCT GRVL, to refresh your reminiscence, for sad causes final 12 months I discovered myself with a model new Salsa Stormchaser body and fork:

The Stormchaser has switchable dropout plate thingies and will be arrange both singlespeed or geared, which is fairly cool, and this body was the to be the premise for a bikepacking challenge my pal didn’t dwell to finish. I figured because it was each model new and a gravel bike the body can be simple to promote, however regardless of itemizing it on the Greg’s Record and pricing it properly under what they go for from Salsa (One Thousand Twelve Hundred and Forty-9 American Enjoyable Tickets, in case you’re questioning) I obtained nary a nibble, and no readers of this weblog reached out to buy it both. So I modified tack, and as an alternative of attempting to promote the body and fork, I made a decision to assemble* the bike.

*[One of my 2026 resolutions is not to say”build” in this context, since it implies you did something more than you actually did, unless you actually welded the frame. I also don’t like when people call a bike “a build.” It’s not a build, it’s a bike. Why say “nice build!” when you can just say “nice bike“ instead?]

Anyway, so far as constructing assembling the bike, my reasoning was two-fold: 1) Maybe a whole bike can be extra more likely to discover a purchaser; and B) I’m the one that’s all the time complaining about gravel bikes and new requirements and stuff, so perhaps as an alternative of whining I ought to attempt to truly study a factor or two about them as an alternative. And what higher approach to take action than by placing one collectively and really driving it for awhile?

And thus, PRJCT GRVL was born.

My pal had left behind lots of the parts crucial to finish the bike–together with digital shifter and derailleur and hydraulic brakes from SRAM. Nonetheless, whereas I used to be seeking to study new issues, I wasn’t seeking to study that many new issues. So I offered the issues that scared me and used the proceeds to buy a Microshift Sword Black drivetrain and a pair Shimano mechanical brakes, in addition to a handlebar and another stuff the bike would want, as a result of if I’ve discovered something from years of biking, it’s that bikes simply work higher with handlebars:

And right here’s the bike:

I shall now relate my experiences with the meeting.

Wheels and Tires

The wheels are Stan’s Crest rims (tubeless, clearly) and the hubs are Bitex. My pal all the time constructed his personal wheels (sure, you may say “constructed” on this context), and these parts are in step with his value-over-flash sensibilities. The rear wheel was already full however the entrance wheel nonetheless wanted to be tensioned, which I undertook myself, and whereas I’m concerning the furthest factor from an professional wheelbuilder thus far so good.

As for mounting the tires, whereas I’m primarily a tube man, I’m additionally no stranger to tubeless. My erstwhile Engin was seet up that approach, and so after all is the Jones, as a result of no matter it’s possible you’ll consider tubes versus tubeless, utilizing tubes in 3″ tires is simply loopy. Nonetheless, mounting these specific tires on these specific wheels was tough. Very tough. Actually it took me two days, although this included going to the bike store to get thinner rim tape. (Apparently I wanted that additional fraction of a millimeter.) My unique intention was to make use of tubes to start out after which simply do the tubeless factor later, however after I noticed how tough the tires had been to mount I knew there was no approach I used to be going to wish to take them off once more to take away the tubes (assuming I might even get the tires mounted with the tubes in there within the first place), and so I went tubeless from the beginning.

Thankfully, as soon as I did lastly get the tires on and regained using my thumbs, I used to be capable of seat them with an everyday flooring pump with out an excessive amount of trouble, little question due to the tight match. I then injected some Orange Seal in there and so they’ve been holding air properly ever since. So all is properly, although I belief my rim taping solely marginally greater than I belief my tubular gluing, and hopefully I by no means must take them off once more.

Brake and Shifter Cables

As soon as I had the tires mounted I believed the exhausting stuff was behind me. I couldn’t have been extra flawed. Getting the cables by way of the body was nothing in need of traumatic, and perhaps essentially the most tough factor I’ve ever needed to do to a motorbike.

Look, it’s not like I simply caught the housing in there and blindly noodle-stabbed on the body hoping they’d make their approach by way of to the opposite finish in some way. First I ran the cable by way of there, which was simple sufficient, after which tried to make use of it as a information and sheathe it with the housing. However this was very tough to do with the shifter housing, and it was extraordinarily, maddeningly, I’m-about-to-cry tough with the brake housing. By the best way, when you’re questioning what path the cables take, they exit by way of the downtube, go over the underside bracket shell, after which into the chainstays:

Even getting the brake housing to make that bend on the backside bracket to return contained in the body was actually, actually exhausting. Possibly it’s simpler with hydraulic hoses, I dunno. Additionally, they’re not crossed on function, the housing simply took no matter path it needed to and that was that. Little doubt extra skilled individuals will inform me all of the issues I did flawed and all the opposite tips I might have used, however I’m not exaggerating once I say it took me 4 hours to make this occur. Like, I used to be up till midnight, and it wasn’t even New Yr’s Eve!

Anyway, it’s finished now, however I actually must surprise: why do they do that? Like, what benefit is there to operating the cables contained in the body? I suppose it appears to be like somewhat higher, however is that each one it’s about? I can’t think about there’s any aero profit to it on a motorbike like this. Right here’s how Salsa describes the Stormchaser:

If reliability is the aim, doesn’t maintaining the cables exterior of the body make the bike way more serviceable? You’re utilizing a full size of housing anyway, it’s not like that you must run them by way of the body to guard them from dust or mud–and if something, can’t mud get inside these open body tubes? Anyway, no matter, it’s finished, and just like the tires I hope by no means to must do it once more.

Listed here are the cables exiting the stays, and I nonetheless get choked up once I take a look at them:

Brakes

After routing the housing, the precise set up of the brakes was fairly simple, although I did must study a factor or two so as to take action. For instance, this was my first set of wheels with centerlock rotors. Fortunately, the lockrings use the identical splined instrument that the Hyperglide cassette lockrings you’ve used for 30 years do. Unhappily, the cassette lockring instrument you’ve had for 30 years in all probability doesn’t match over a thru-axle…or at the least mine didn’t. This meant I couldn’t use it for the rotors or for the cassette. So I needed to buy a brand new instrument on the bike store, which is okay, as a result of it’ll proceed to turn out to be useful and also you hardly ever remorse having extra instruments.

Additionally, whereas I’ve loads of expertise with mechanical disc brakes, I’ve no expertise with flat mount disc brakes, and so I needed to study adapters. I had a pair of 160mm rotors, and I had a entrance brake that got here with an adapter you orient accordingly relying on whether or not you’re utilizing a 140mm rotor or a 160mm rotor, and I couldn’t for the lifetime of me determine why the adapter didn’t match on the fork in both course…till I lastly discovered this specific fork is designed for a 160mm rotor solely and that you simply bolt the caliper on to it, so that you don’t want the adapter in any respect.

In the meantime, the rear brake didn’t include an adapter, which it turned out I’d want in an effort to use that different 160mm rotor. So first I attempted to make use of the SRAM 160mm adapter I nonetheless had, however–shock!–you may’t try this as a result of the engineers at SRAM clearly designed it particularly to forestall you from permitting it to the touch a Shimano caliper. Then I went to the bike store, however they didn’t have an adapter, and moderately than allow them to order one and have to attend for it, or else undertake a loopy scavenger hunt going from bike store to bike store, I simply purchased a 140mm rotor from them as an alternative, because you don’t want an adapter for that. Certain, the rotor was dearer than the adapter would have been, however after spending two days on the tires and 4 hours on the cables I didn’t wish to delay the challenge any additional…and anyway, consider all the burden I’m saving with out the adapter and the additional 20mm of rotor!

(Plus I now have a spare 160mm rotor for when the entrance wears out in 20 years.)

However I’m not mad on the disc brakes. Sure, the entire above was a little bit of a trouble, nevertheless it was solely as a result of I didn’t know what I used to be doing; now that I do know concerning the adapters I’d know what I wanted if I ever needed to work on one other body with flat mount calipers. (Oh, additionally, you’ve acquired to know what size mounting bolts your body wants, however happily those I had available occurred to work.)

There’s one different potential subject when coping with mechanical disc brakes, which happily I narrowly averted. See how shut the cable noodle thingy is to the fork?

Working the cable by way of the fork and into the caliper was a really tight match certainly. (And no, I couldn’t have gotten rid of the noodle, the housing wouldn’t have managed the tight flip immediately into the caliper.) I used to be relieved that I used to be capable of make it to work, and I recalled {that a} reader who got here by my house to choose up a motorbike a couple of months in the past had a Paul mechanical brake on his personal bike that wouldn’t enable him to run the cable by way of the fork in any respect–as an alternative he needed to zip tie the housing to the fork leg or one thing. Anyway, all of that is to say that clearly mechanical brakes will be tough with this GODDAMN INTERNAL CABLE ROUTING, and little question it varies fairly a bit from bike to bike and caliper to caliper. On this case I acquired fortunate, however sooner or later I’d do some analysis to ensure they work collectively first.

Oh, one other completely happy accident is that these specific brakes don’t have a barrel adjuster on the caliper. As an alternative, when you’re utilizing them on a motorbike with out cable adjusters on the brake lever or on the cable cease or one thing, you utilize inline adjusters, which you’ll see alongside the cables slightly below the handlebars:

Why is that this a contented accident? As a result of if I ever want to elongate the brake cable housing for some motive (I’m unsure why I’d, however no matter) I don’t have to re-route it by way of the body once more. As an alternative, I can simply change the part of cable upstream from the adjuster. (Or would that be downstream?) See? Looking back I’m a genius!

(Oh, and when you’re questioning how properly the Shimano mechanical brakes work, thus far I’m more than happy with them…although needless to say’s coming from a dedicated rim brake person.)

The Crank

This was the crank configuration my pal left behind–it’s a Race Face crank with an Easton spider and an oval-shaped Wolf Tooth chainring.

Like flat mount disc brakes, I’m largely illiterate relating to trendy crankular chainring attachment interfaces and what goes with what–however since my pal had chosen the elements already I didn’t really want to fret about it. The Stormchaser body takes mountain bike cranks, so I suppose his method was to make use of the spider so it could readily settle for extra road-and-gravel-appropriate chainrings.

As for assembling all of it, this too was pretty easy, because the crank makes use of the identical exterior backside bracket as a Hollowtech II, and the lockring for the spider or chainring accepts the identical instrument you have already got in your outdated cartridge backside bracket. Straightforward! Nonetheless, the one quirk right here is that the Race Face crank requires 61Nm of torque, and when you don’t know the way a lot that’s, it’s loads. And I imply loads–much more than different similarly-designed cranks. Like, I put in it as exhausting as I presumably might with a reasonably long-handled Allen key, and once I ultimately checked it with a torque wrench I discovered it wasn’t even midway there. Arguably no bicycle part ought to require that a lot torque, particularly when Shimano has confirmed you may design a crank that matches collectively reliably with a easy preload cap and a few pinch bolts. (Certain, they then proceeded to spoil it by gluing it collectively, however that’s a separate subject.) Then once more, in equity to Race Face, the set up directions are fairly clear, and I suppose when you fail to make use of a torque wrench and also you spoil the splines in your crank then that’s your drawback.

The Drivetrain

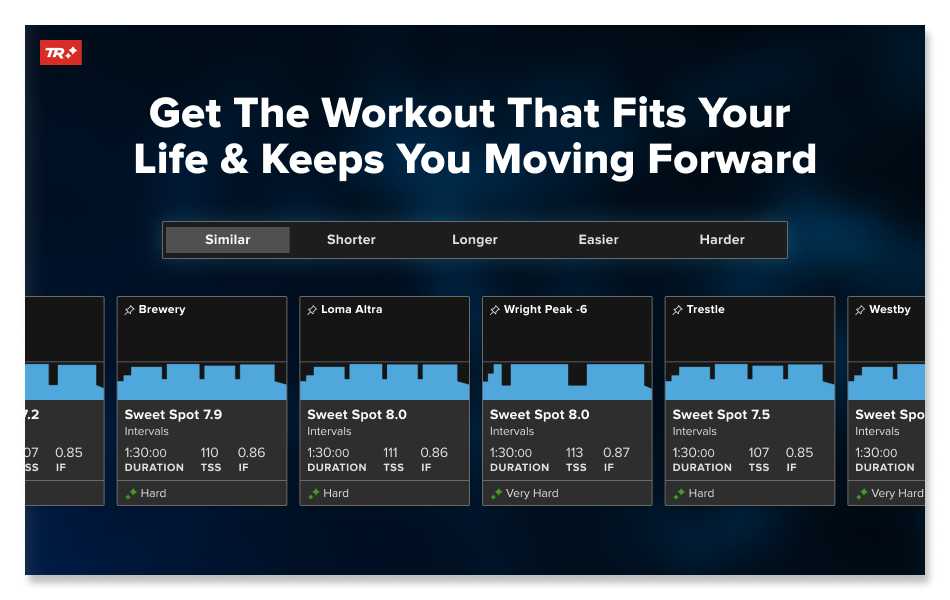

Like many bike dorks I instantly favored the sound of Microshift Sword Black, the dirt-cheap 9-speed mechanical-only drivetrain that comes with a sq. taper crank. (Although I didn’t purchase the crank since I already had the Race Face able to deploy.) So I used to be very excited to strive it out. And in contrast to among the different parts on the bike, the Sword Black stuff was extraordinarily simple to put in, with completely no surprises in any respect.

As for the way it works, whereas I’ve solely acquired a couple of rides on it, thus far I prefer it very a lot. Nonetheless, I do want to deal with that upshift nubbin:

You’ve acquired to really feel for Microshift. Shimano, Campagnolo, and SRAM took all the nice shift lever positions, and so all they had been left with was the nubbin, which simply hides there, like a uvula or a clitoris:

Additionally like a clitoris, it may be somewhat exhausting to search out when you’re inexperienced–particularly when you’re sporting lobster gloves:

Granted, you’re in all probability not going to be sporting lobster gloves once you’re pawing at a clitoris, however it’s possible you’ll very properly be sporting them when you’re driving a motorbike within the chilly, and in reality that is usually what I’m sporting on the bike when the temperature is properly under freezing, because it was once I lastly completed the bike.

[“Awww, you wear lobster gloves when it’s freezing? I don’t even bother with pants until absolute zero on the Kelvin scale.”]

With regular gloves it’s a lot simpler to finger the nubbin, although it’s nonetheless not fairly as intuitive as the opposite methods. (Or a bar finish shifter, for that matter, which you should use even when you’re sporting an oven mitt.) After all, as I say, it’s solely been a couple of rides thus far, and I’m certain as soon as I’m used to the nubbin I gained’t even give it some thought–and even now, whereas I’m nonetheless not used to it, I by no means remorse the acquisition. However given how good all the things else concerning the Sword Black stuff appears to be thus far, the nubbin stands out because the one space that might use somewhat enchancment, or at the least some extra floor space. However perhaps if I rub it lengthy sufficient it’ll get larger, I dunno.

Anyway, there you will have it, I put collectively a gravel bike all on my own (properly, apart from all of the stuff my pal had already finished, and apart from asking the store to knock within the star nut for me since I don’t have the instrument):

BK SNB GRVL?!? Absolutely now the gravel development is formally over. Higher dump all of your shares of Life Time Inc…