The brand new lineup provides flax, cuts weight, and ski actually, rather well

With a start-to-finish manufacturing facility in Salt Lake Metropolis and Wasatch testing floor a mere 33 minutes aside sans site visitors, it’s no shock that DPS is ready to pump out significant updates to their skis on quick timelines. The grasp ski tinkerers have unveiled the brand new 2024/2025 Carbon Pagoda Touring lineup, which will probably be touchdown in a retailer close to you, like Cripple Creek Backcountry, someday this fall.

The massive information about DPS’s new Carbon Pagoda Tour CFL household is flax. Sure, the fiber from the seeds in your granola that people have been utilizing for hundreds of years. The brand new flax fibers are woven instantly into the carbon fiber sheets that sandwich the wooden cores to additional dampen vibrations. Different updates embrace bio-based epoxy resin and 60% algal sidewalls from DPS’s neighbor, Checkerspot, all through the road.

Wildsnow testers have raved about DPS touring skis for years. Slator Alpin toured their earlier manufacturing facility and detailed their ski constructing course of again in 2020. At present, they’re handmade in DPS’s personal manufacturing facility within the coronary heart of Salt Lake Metropolis’s Granary District, using roughly 50 full time workers.

As a part of their launch, DPS invited esteemed out of doors writers and media shops to a 3 day launch, ski take a look at, and manufacturing facility tour of their Salt Lake Metropolis house at the start of April. I used to be capable of weasel my manner in, too.

Over the course of three days, DPS’s advertising and marketing workforce shepherded the small media crew by the manufacturing facility, a mogul-bashing, steeps-ripping, piste-carving take a look at day at Alta, and a guided backcountry tour within the Wasatch’s Little Cottonwood Canyon.

Touring in little Cottonwood Canyon

DPS

However first, like all good launch, it began with a crisp powerpoint within the coronary heart of DPS’s hyper-modern shared workplace house. Constructed from and integrating the historic remnants of a locomotive manufacturing facility, it was brimming with tech startups, glowing shared kitchens, ping pong tables, and espresso machines buzzing away. It was arduous to think about that the ski firm may very well be something however the oddball on this constructing. However much less polished than the crisp, techy workplaces surrounding it, DPS’s foremost workplace was extra what you’d anticipate: Historic skis lining the partitions, ski posters in all places, and ski individuals bustling about engaged on ski issues passing out and in of the adjoining manufacturing facility.

Resins are essential to holding all of it collectively. DPS makes use of bio-based resins from Texas.

There’s extra to DPS than simply fancy light-weight backcountry skis. Since their founding in 2002, They’ve pioneered the Phantom Wax system, partnered on a line of ATK bindings with just a few particular tweaks for the North American market, and so they additionally make skis for the US Army together with the tenth Mountain Division. After eight years producing skis in Asia, they introduced manufacturing stateside in 2013. Since then, they’ve outgrown two different factories in SLC. However regardless of the excessive tech elements and engineering, their common ethos stays simple: “Construct the most effective skis we are able to, and hope individuals like them,” described DPS’ Senior VP of Operations, Thomas Laakso.

DPS SVP Thomas Laakso sending it on tech bindings

Contained in the Carbon Pagodas

As we rode up the primary chairlift after the manufacturing facility tour, I peppered Thomas and DPS’s World Advertising Supervisor, Zach Clayton, with questions on carbon, flax, fiberglass, and different ski elements. Thomas talked about that carbon, not like fiberglass, has an infinite fatigue life – they received’t break down within the core of the ski from repeated flexing like fiberglass does. Given their push to construct skis with lengthy lives, it’s a no brainer. The catch is that carbon is six instances dearer than fiberglass on a gram-per-dollar foundation. They’re additionally sourcing it from an aerospace producer in SLC.

Thomas is a supplies engineer by coaching, however now “performs an engineer on TV” as he put it, working as an alternative on what looks like a giant function in ski growth at DPS. The person is obsessive about supplies – wooden, carbon, flax, epoxy – all of it. And it’s an obsession he shares with others on the workforce. No bases are adequate, for instance, aside from World Cup high quality P-Tex 4000 race bases from Austria.

There’s an elephant within the manufacturing facility and the DPS workforce addressed it head-on: DPS skis are costly. Much more costly than different skis, even their high-end rivals pumping out of factories in Europe and Asia. Their 23/24 Carbon Pagoda Tour skis retail at practically $1,700.

DPS doesn’t stand for “Double Priced Skis,” Thomas joked.

Sheets of carbon sandwich the cores within the DPS manufacturing facility. Carbon is pricey.

Jokes apart, DPS takes their craft severely. Based mostly on what I noticed, heard, and felt for myself, they aren’t prepared to stint on supplies, sourcing, sturdiness, or efficiency traits to hit worth factors. On high of that, they’re eager on sourcing supplies domestically when their requirements might be met. Edges, for instance, are manufactured within the midwest. Resins come from Texas. And like mainly every little thing else, uncooked supplies are getting dearer. These Texan resins, for instance, have elevated in worth by practically 80% up to now few years. Paying a residing wage to staff in Salt Lake Metropolis isn’t getting cheaper both. It is smart, then, that DPS skis aren’t getting cheaper.

Snowboarding the Pagoda Household

As we pushed off into the primary run of the day, it was straightforward to really feel the relative dampness and really even flex fore and aft whereas arching huge activates Alta’s groomed entrance facet. I felt snug on the inexperienced 90mm waisted Carbon Pagodas after only a few turns; They had been intuitive proper off the bat and I felt practically as much as full pace behind Thomas, who was ripping deep activates an experimental frontside ski they’ve been tinkering with.

After just a few runs, I bumped as much as the Pink 100 underfoot skis in the identical size. Although their cores are equivalent, their shapes are fairly totally different. The 100’s function a tapered tip and tighter sidecut, leading to a 15m flip radius in comparison with the 90’s 18m flip radius.

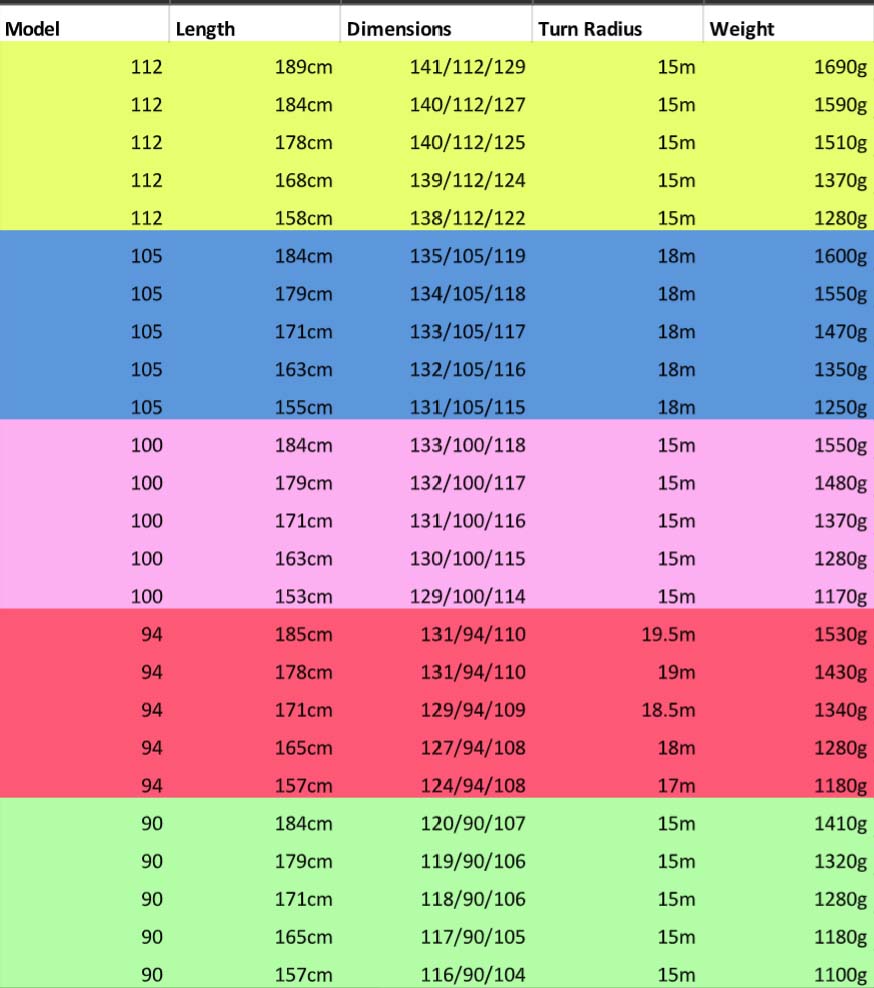

The skis within the new Carbon Pagoda Tour household alternate flip radii as they go up in waist dimension slightly than forming a linear development of accelerating or reducing flip radius. So choosing the right ski to your type takes slightly extra thought than simply grabbing the underfoot width you’re after.

Zach and DPS’ Advertising Coordinator, Erin Spence, guided us to a few of Alta’s steeper terrain, which was graced with distinctive tender chop circumstances. Each ex-racers, they tore into it with out a lot regard for conventional limitations of light-weight skis.

I felt snug pushing the 100’s proper out of the gate, too. As the form and sidecut would recommend, they had been fairly agile, but didn’t really feel nervous. I used to be capable of push into my Scarpa Maestrale RS’s and energy by the uneven circumstances, pop round, and put the skis the place I needed them. Would I need one thing beefier, damper, and slightly straighter for day in, time out resort snowboarding? You guess. The Carbon Pagoda’s are devoted light-weight touring skis, however I wasn’t left wanting rather more in these tender circumstances. That huge 130 flex boot felt effectively matched, neither over nor underpowered for the whole Pagoda lineup.

I took the darkish blue 105’s, that are a brand new form completely for the Carbon Pagoda household, out for the previous couple of runs of the day. Additionally they featured the identical core, however bounced again to the longer 18m flip radius, which felt extra steady and skied longer, as anticipated. “A stable ski for tender circumstances, however sufficient chew for steep agency snow. Form of a light-weight crusher” is the notice I hammered out on the chairlift.

I requested Zach why they didn’t use any titanal within the ski underneath the binding plate. They mentioned the Pagoda’s didn’t want them – they had been capable of obtain the binding retention with a P-Tex 4000 insert (similar materials as the bottom) and the carbon/Paulownia combo supplied the torsional stiffness they had been after. Plus, no steel within the ski means they’re capable of skip the extra materials, its extra price, weight, and carbon footprint.

I imagine them. From what I might inform over two days of testing, the torsional stiffness in every of those skis felt plentiful. We continued bashing by tender moguls and steeps till the lifts shut down. I pushed every ski as arduous as I might and had a number of enjoyable doing it. We skipped the Alta Bombs, for higher or worse.

Touring

The subsequent day our gaggle of writers, two guides from The Backcountry Execs, and DPS workers tossed the DPS branded ATK’s into tour mode and skinned up the opposite facet of Little Cottonwood Canyon for just a few backcountry laps. One of many guides was fittingly driving a 12-year-old pair of Wailers, complimenting the advertising and marketing workforce’s sturdiness assertions as in the event that they had been planted.

I took the brilliant pink 100mm underfoot 184cm skis for the day. As anticipated from such a lightweight pair of skis, they felt gentle on the pores and skin monitor. The comparatively conventional mount factors made them a breeze on kick turns. The torsional stiffness gave them a assured edge on the frozen solar baked crust.

Like just a few different firms, DPS has their very own line of bindings made by ATK. However Wildsnow readers will probably be psyched to listen to that DPS insisted on 0 diploma ramp angles as an alternative of ATK’s commonplace, so that they machined a customized base plate. Oh, and black screws had been a should.

Over the course of the day, we skied by the complete vary of backcountry circumstances – deep, steep powder, heavy spring corn, wind affected snow, and so on. Like my expertise the day earlier than, the 100’s suffered virtually nowhere for such a lightweight pair of skis. They felt exceptionally nimble, however weren’t timid once I opened up the turns.

DPS World Advertising Supervisor, Zach Clayton, hucking a backcountry backie

I wasn’t capable of faucet in a light-weight boot, however I’m assured that the 100mm, 94mm, or 90mm waisted skis within the 179cm size can be an ideal match for my Scarpa F1 XT’s. That’s a pairing I’ll be testing later this spring, so I’ll get again to you on that one.

Conclusions

I haven’t had practically sufficient time on any of those skis to place collectively a complete overview (that can hopefully change), however the notes I took over two days of testing level me towards just a few early conclusions:

The brand new Carbon Pagoda Tour CFL household ski exceptionally effectively for his or her scant weight.

They’re actually costly and now I perceive why.

The individuals working at DPS are obsessive about the trivia of ski craftsmanship. They’d slightly do it themselves than outsource.

Alta and the Wasatch backcountry are unimaginable testing grounds for a ski firm needing quick suggestions in numerous terrain and circumstances. All the businesses primarily based in SLC are clearly manner forward of me on this one.

DPS stands for Sturdiness, Efficiency, Sustainability, which isn’t the unique acronym

Utah’s beer legal guidelines are foolish

If I needed to choose one pair of the skis from the lineup to be my solely ski for a complete season in Colorado, it might be the 100mm underfoot model within the 184 size. They’re simply so dang enjoyable and nimble.

DPS’s 2024 Pagoda Tour Lineup seems like this:

Bergen Tjossem is a ski fanatic, conservation skilled, and nature nerd primarily based in Vail, Colorado. His life and profession have centered round defending the pure setting and public lands that raised him, however as Ed Abbey put it, “It isn’t sufficient to struggle for the land; It’s much more essential to take pleasure in it.” So when he’s not working his day job, you’ll discover Bergen ski touring earlier than daybreak, mountain climbing at nighttime, working trails till his legs fall off, snowboarding 13er’s along with his pals, or making the world’s greatest pizza along with his spouse, Rachel. Yow will discover him on Instagram.