Within the industrial sprawl north of Indianapolis, within the coronary heart of the American Midwest, just a few miles north of the long-lasting oval Indianapolis Motor Speedway, a monolithic warehouse bears the enormous pink emblem of US part manufacturing big SRAM. Beside it’s the extra modest emblem of its sister model Zipp.

It is an ironic order of significance, as inside this huge, hangar-like house is among the few locations outdoors Asia making carbon bike parts at scale. It’s right here that Zipp’s Trip Prepared SW and NSW wheelsets are made.

“You may provide you with the best concepts, but when any individual can’t make it in an affordable time and with an affordable talent set, it’s not an awesome design,” says Ruan Trouw, SRAM’s Manufacturing unit Engineering Supervisor, as we stand on the manufacturing unit ground.

“We’ll sometimes set a lead time relying on present demand, however we attempt to get it performed the identical day the order is positioned – so long as it is available in at an affordable time. We’ll transfer these orders by way of as they arrive; such as you noticed on the hour-by-hour chart, we plan the entire day based mostly on buyer orders. However for Trip Prepared, they basically soar the road – we get these rims to that particular cell and begin constructing these wheels during to boxing.”

Beneath, we define as a lot as we will of the manufacturing from begin to end, and all of it begins in big freezers…

The Zipp facility’s checkered facade is a nod to the speedway, which acts as a sporting centre of gravity for this complete area.

The Zipp 2001 is a chunk of motorcycle design historical past, and continues to have a cult following. The body is only one a part of a wealthy museum of SRAM and Zipp parts adorning the power right here in Indianapolis.

Industrial fridges home the pre-impregnated (generally referred to as ‘pre-preg’) carbon fibre sheets forward of wheel manufacturing.

“We reduce the uncooked unidirectional into particular shapes, lay them up on tables with the called-for orientations, then reduce these sheets into strips,” Trouw says.

These sheets are reduce into strips, which transfer to stream cells the place operators hand-place them at particular stations

The strips are then put into a selected layup sample. That is basically the recipe of the wheel, earlier than it is cooked.

“Strips get handed down into the cells, the operators have particular spots. It’s damaged out into small assembly-line kind chunks of labor. Every operator will place carbon and move it alongside,” Trouw explains.

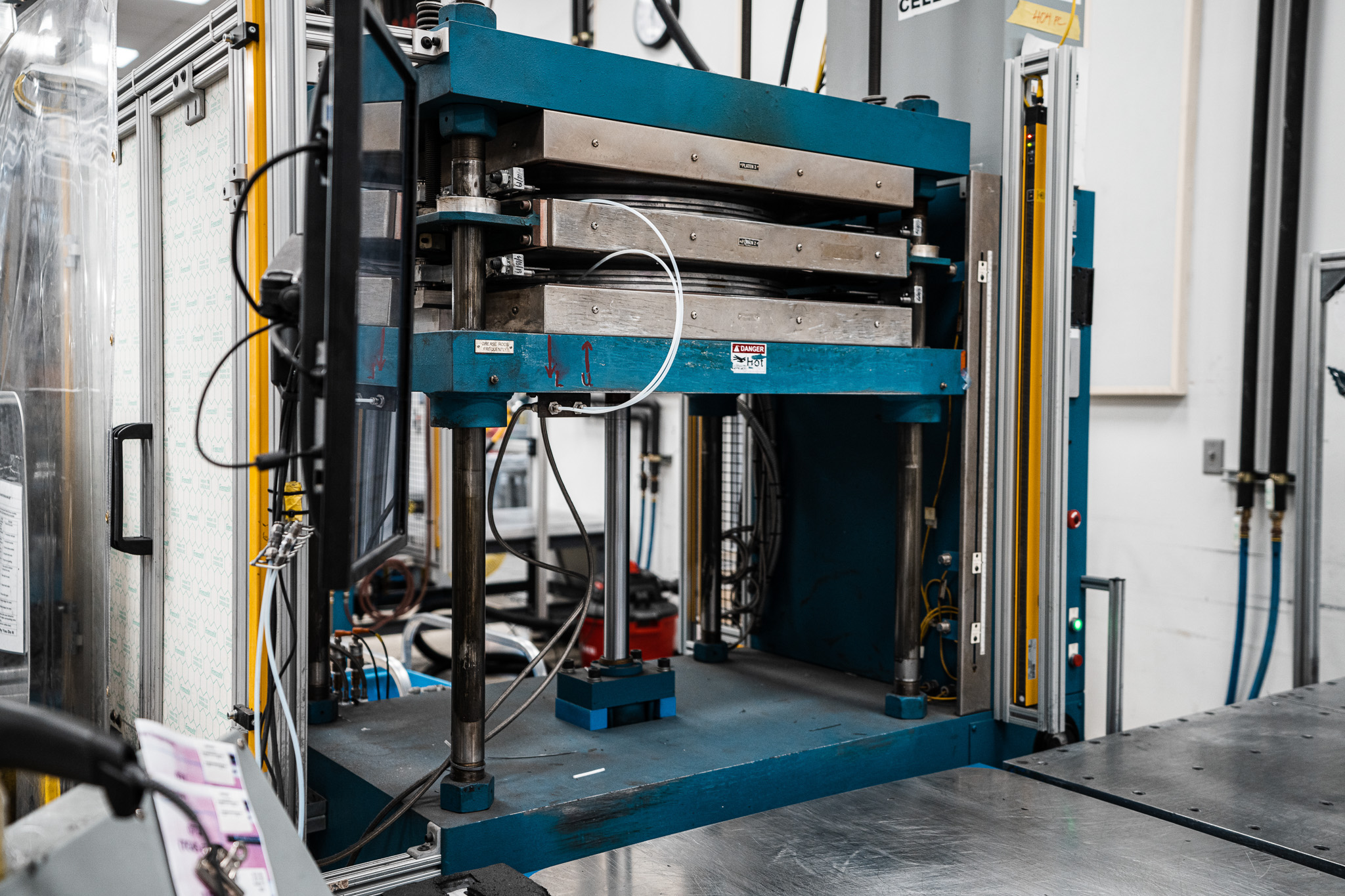

“From there, [the rim] goes right into a press and will get moulded,” Trouw explains. Zipp makes use of heat-press moulding to warmth after which treatment the carbon. Every little thing is rigorously measured and modelled to finite accuracy.

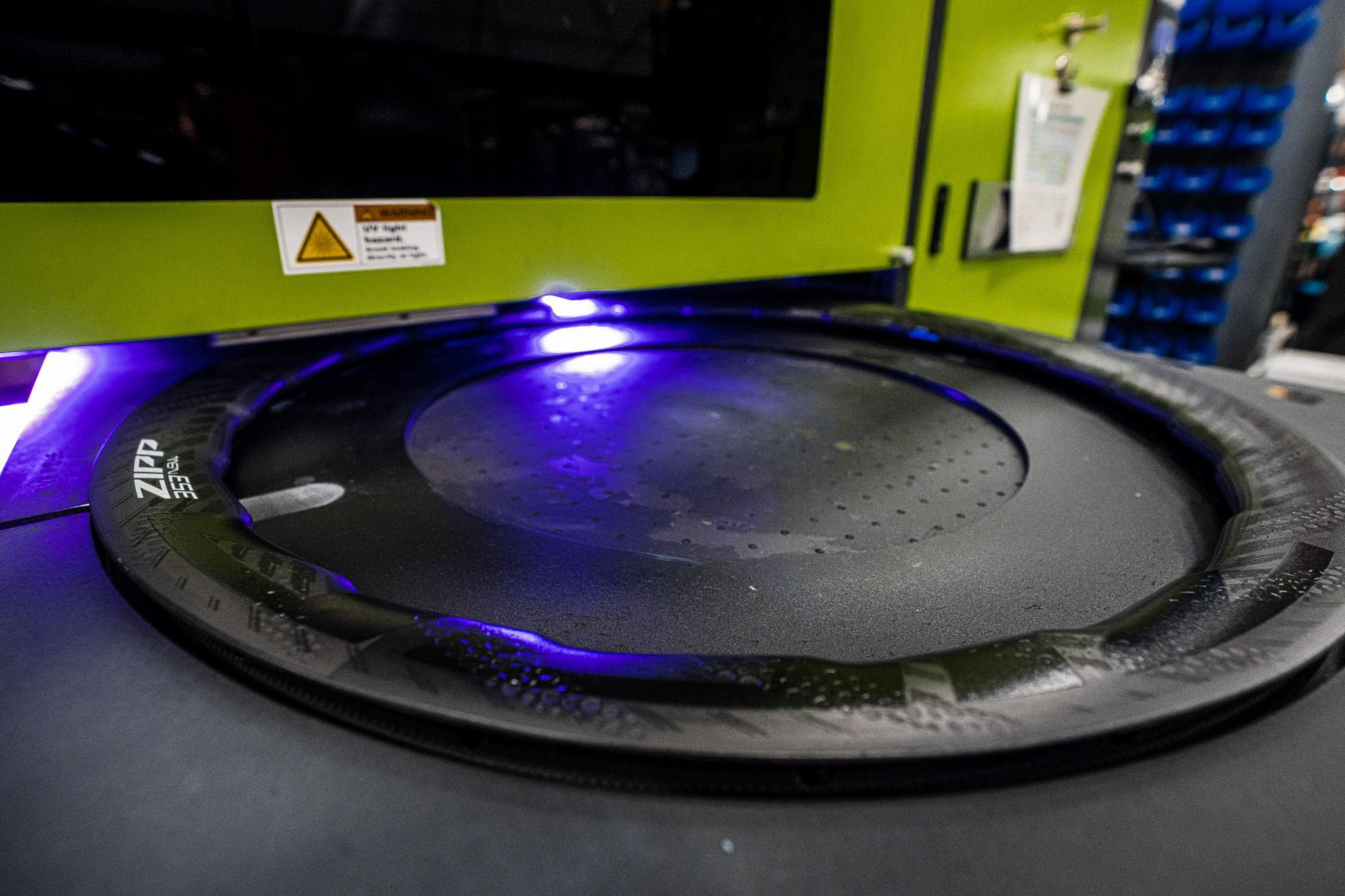

“As soon as they’re out of the press, now we have to undergo a deflash course of,” Trouw explains. “So all your break up strains on the instruments will go away a flash line of resin. We’ve got to take away that resin.”

“As soon as that’s eliminated, we’ll begin with the valve gap first. First drill a valve gap, after which the valve gap is what helps us additionally find spoke holes. And so it’ll go right into a machine to drill spoke holes.”

“After that, we clear up the rim, take away the bladder, after which because it goes into type of a closing examine state,” Trouw explains.

“Then that can get fed with the edges down just a few completely different manufacturing strains,” Trouw says. “If it will get printed, [it goes to the] printing station first. If it’s a decal rim, it’s going to find yourself going to wheel construct first, after which get decaled.”

There are endearing part thrives throughout the manufacturing unit ground. A set of handlebars to steer a trolley, or a bit of carbon rim used for a sealant-adding station.

From the market space, rims are matched with hubs, spokes, nipples, and decals in a kitting course of earlier than heading to the construct strains.

“Printed rims go to wheel construct after printing, the place they’re laced, constructed, and eventually boxed,” Trouw says.

The Zipp manufacturing unit is a shrine to the model’s manufacturing and racing heritage. The partitions are actually lined with disc wheels.